Lovibond® Colour Measurement Instruments & Solutions for Every Industry

When precision matters, Lovibond® delivers. Our world-class colour measurement instruments and colour measurement solutions help businesses ensure product consistency, regulatory compliance, and visual quality across a wide range of industries—from edible oils and beverages to chemicals, cosmetics, and fuels.

With over 140 years of expertise in color science, we understand that accurate colour control isn’t just cosmetic—it’s essential for product quality, safety, and customer trust. That’s why professionals around the world rely on Lovibond® for their most critical colour measurement applications.

What is Colour?

Colour is a visual, perceptual property in human beings. Colour is derived from the signals produced by three different types of light sensitive cell in the eye that respond to the spectrum of light (distribution of light energy versus wavelength). In our environment, materials are coloured depending on the wavelengths of light they reflect or transmit.

The visible colour spectrum runs from blue through to red wavelengths, approximately 360-720 nm. Three things are necessary to see colour:

- A source of light

- An object

- An observer/processor

Communication of Colour

How would you describe the colour of this Juice? Would you say it’s orange, orangish yellow or maybe a bright canary yellow?

Each person verbally describes and hence defines the colour of an object differently. As a result, objectively communicating a particular colour to someone without some type of physical standard is difficult.

Also describing in words the precise colour difference between two objects is very challenging. Your perceptions and interpretations of colour and colour comparisons are highly subjective.

Eye fatigue, age and other physiological factors can influence your colour perception. But even without such physical considerations, each observer interprets colour based on their personal perspective, feelings, beliefs and expectations. For example you may convince yourself that a certain colour match is within tolerance if you are under pressure to declare a colour match as acceptable. The solution to this dilemma is an instrument that explicitly identifies a colour by measuring it and comparing the colour to standards completely objectively and accurately each and every time. That is, an instrument that differentiates a colour from all others and assigns it a numeric value.

Colour measurement, also called colorimetry, is the process of accurately analyzing the colour of a material or substance. Using colorimeters and spectrophotometers helps translate colour into numerical data, ensuring consistency and quality in products across various industries.

Accurate colour measurement is crucial because of the benefits it offers

- For maintaining product consistency and meeting industry standards.

- It helps ensure uniform colour across batches, which is essential for branding and consumer trust.

- It also improves manufacturing efficiency by identifying colour deviations early, reducing waste, and supporting regulatory compliance, especially in industries like food, pharmaceuticals, and chemicals.

- Helps maintain quality and efficiency in production.

- Allows faster turnaround time and report generation.

Lovibond® provides intuitive, easy-to-use colour measurement instruments that offer precise and reliable results.

Ways to Measure Colour

Today, colorimeters, spectrophotometers and spectrophotometric colorimeters (sometimes referred to as spectro-colorimeters) are the most commonly used instruments for measuring colour worldwide. These technologies measure the proportion of reflected or transmitted light at many points in the visible spectrum. The points can be plotted graphically to form a spectral curve. Since the spectral curve of each colour is completely unique, like a signature or fingerprint, the curve is an excellent tool for identifying, specifying and matching colour.

When an object interacts with light, some of the wavelengths of light are absorbed and others are reflected or transmitted (in the case of a coloured but clear liquid). Therefore a red ball absorbs all wavelengths of light except for those in the red part of the spectrum, which it reflects.

A blue ball reflects only blue wavelengths. A glass of apple juice transmits green and yellow wavelengths. Fresh snow reflects most of the light that interacts with it and hence appears white. Black is due to the absence of reflected light.

Transmission

Transmission in Colour Measurement refers to the amount of light that passes through a sample when it is illuminated. It's a measure of how much light is transmitted through a substance as opposed to being absorbed or reflected.

In colour measurement, transmission is typically measured using a spectrophotometer or a colorimeter that illuminates the sample with a specific light source and detects the amount of transmitted light at different wavelengths. This helps in accurately determining the colour and transparency of the material

For example, when testing a liquid sample, such as a beverage or chemical solution, you should be able to read text placed behind the liquid if it has high transmission.

Understanding Transmitting and Reflectance Samples

What Are Colour Measurement Instruments?

Colour measurement instruments are devices designed to quantify and standardize the appearance of materials based on internationally recognized color scales. Unlike visual judgment, which is subjective, these instruments deliver objective, repeatable values for color across liquid and solid samples.

Lovibond® offers a wide range of colour measurement instruments to suit different testing environments, from simple visual comparators to high-precision spectrophotometers with advanced software integrations.

Our Colour Measurement Instruments Include:

- Spectrophotometers (PFXi Series) – Ideal for oils, fuels, and chemicals

- Visual Comparator Systems – Compact and widely used for edible oils, water, and chemicals

- Automatic Colourimeters – For high-throughput QC environments

- Custom Calibration Standards – To ensure ongoing accuracy in colour measurement instruments

- Application-specific scales – Lovibond®, Gardner, Saybolt, AOCS, RYBN, EBC, and more

All Lovibond® colour measurement instruments are backed by certified calibration, software compatibility, and international compliance.

Colour Measurement Solutions for Every Sector

We provide industry-specific colour measurement solutions that help companies meet national and international color quality standards.

Our instruments are used by:

- Oil Refineries & Edible Oil Producers

- Food & Beverage Manufacturers

- Pharmaceutical & Cosmetics Companies

- Chemical & Petrochemical Plants

- Environmental Monitoring Labs

Whether you're grading mustard oil with the AOCS Tintometer scale or verifying diesel with the Saybolt index, our colour measurement solutions simplify your workflow.

PFXi-880,- 950, -995

Spectrophotometric Colorimeters with Extended Path Length & Optional Heater...

Model Fx

The Lovibond® Model Fx solves the temperature problems associated with consistently...

Comparator System

The Comparator 2000+ is an easy-to-use, entry level colour measurement system...

EComparator

The EComparator series advances colour measurement, enabling you to progress...

Model F

The Model F is a visual colorimeter designed to optimise the use of Lovibond® ...

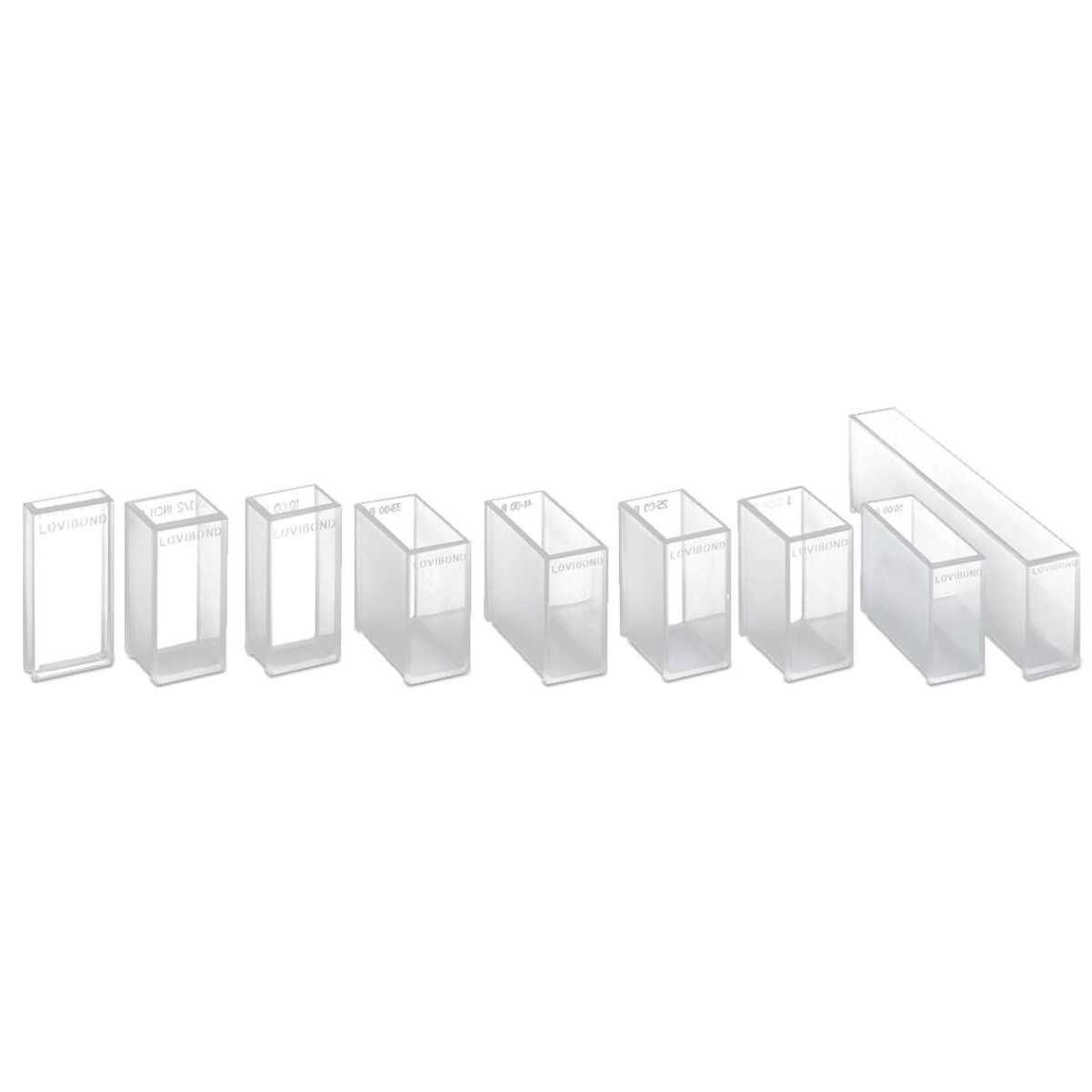

Cuvettes and Cells

These optical glass cells are the heart of the Lovibond® colour measuring instruments...

Standards

Lovibond's certified glass and liquid colour standards. Your benchmark for reliable...

Reflectance

Reflectance refers to the amount of light that bounces off the surface of a sample, rather than passing through it. In colour measurement, reflectance is key to determining the appearance of solid materials, coatings, and surfaces. When light hits the surface, some of it is absorbed, while the rest is reflected back. The percentage of light that is reflected can tell us a lot about the colour and surface characteristics of the material.

For example, when measuring the reflectance of a painted surface or textile, the colour intensity and sheen are influenced by how much light is reflected. A highly reflective surface will appear brighter, while a less reflective surface will appear duller.

In industries such as automotive, textiles, and coatings, reflectance is essential for ensuring colour consistency, product quality, and achieving the desired finish or look. Accurate reflectance measurement helps manufacturers maintain consistent colours and textures across large production runs.

LC 100 SV 100 Kit

The LC 100/SV 100 is a highly flexible and lightweight spectrocolorimeter...

TRA 520 Handheld

The TRA 520 is a cost effective quality control solution, which can be used as...

TR 515

The TR 515 offers accurate and reliable colour management that fits in the palm of...

TG Series- Gloss Meters

The Lovibond® TG Series of gloss meters allow you to measure low, medium and high gloss ...

TR Series- Spectrophotometer

The Lovibond® TR Series of spectrophotometers and reflectance meters...

LC Series- Spectrocolorimeter

The Lovibond® LC 100 & SV 100 spectrocolorimeters offer fast, accurate and precise...

Sphere Geometry:

Reflected light can be measured in a number of different ways: different instrument geometries affect the reading obtained but can be easily matched to your application.

The different instrument geometries do, however, share common elements. Light from a controlled light source and a sensitive light detector are always utilized.

Instruments with sphere geometry have played a major role in colour quality control systems for over 50 years. The sphere has a white inner surface and a small circular aperture, against which the sample is placed to allow colour measurement. Additional apertures allow light to enter and leave the sphere at defined angles.

Why Choose Lovibond® Colour Measurement Solutions?

- ✔ Proven expertise across 100+ countries

- ✔ BIS, ASTM, AOCS, ISO, and WHO-compliant systems

- ✔ German-engineered accuracy

- ✔ Long shelf-life accessories and standards

- ✔ In-country support, training, and validation

- ✔ Software-enabled traceability for audits

Lovibond® combines innovation and reliability in its full range of colour measurement solutions—delivering fast, consistent, and repeatable results.

Benefits of Using Colour Measurement Instruments

- ✔ Objective results – No reliance on human perception

- ✔ Repeatability – Consistent readings across shifts and sites

- ✔ Compliance – Meet standards for color uniformity and safety

- ✔ Efficiency – Reduce waste and improve batch-to-batch control

- ✔ Adaptability – Suitable for liquids, gels, powders, and solids

Our colour measurement instruments are designed to fit seamlessly into your lab or production floor—boosting your quality assurance and minimizing product recalls due to visual inconsistencies.

Localized Solutions for Indian Industry

Lovibond® India supports a wide range of colour measurement solutions tailored to local industries. Whether it’s supporting FSSAI colour guidelines for edible oil, or ensuring cosmetic colour uniformity, our tools help maintain regulatory compliance and build brand trust.

We also offer training, calibration, and service support across India to ensure your colour measurement instruments perform at their best.

Ready to Standardize Your Colour Quality?

Don’t leave color to guesswork. Discover how Lovibond® colour measurement instruments and colour measurement solutions can transform your QC process with accuracy, speed, and confidence.

Before we measure a colour we need to establish a means of describing it, lets start Your Colour Journey

FAQ's

What is a Spectrophotometer and how does it work?

What is a colorimeter and its principle?

What is colorimetetry?

What is RYBN colour scale?

What is Gardener scale and where is it checked?

What is CIELAB System?

The CIELAB system is a colour measurement method developed by the International Commission on Illumination (CIE). It defines colour in a three-dimensional space with parameters:

L* for lightness

a* for red-green axis

b* for yellow-blue axis

Lovibond® instruments utilize the CIELAB system for precise colour quantification, offering unparalleled consistency across multiple industries.

Importance of colour measurement in food?

Colour measurement in food ensures product quality, consistency, and consumer appeal. For example, it helps standardize the colour of beverages, sauces, and bakery items while ensuring compliance with industry regulations. Lovibond's colour measurement solutions allow food manufacturers to maintain high-quality standards and improve customer satisfaction.

Service Request

Service Request  Sales Enquiry

Sales Enquiry  Customer Reviews

Customer Reviews